Key Takeaways:

Key Takeaways:

- Emerging technologies like AI, blockchain, and automation offer transformative solutions for boosting efficiency, transparency, and sustainability in logistics operations.

- Businesses should prioritize factors like adaptability, compatibility, and ROI when adopting logistics technology trends to future-proof their operations.

- Technologies like predictive analytics help mitigate risks by anticipating potential disruptions and enabling proactive measures.

Did you know that by 2030, the global logistics market is expected to skyrocket to over $18 trillion, with a compound annual growth rate of 10.7%?

With such rapid growth comes a big challenge for logistics companies: how to keep up with demand while staying efficient.

Amidst this, technology is playing a bigger role than ever before. There’s a surge of new technologies hitting the market, and logistics companies are under pressure to pick the right ones to stay ahead.

So, here’s the big question: which logistics technologies should businesses focus on to make their operations smoother?

These trends aren’t just futuristic dreams; they’re becoming essential tools for businesses aiming to remain competitive. The possibilities are endless, from artificial intelligence (AI) figuring out the best routes to blockchain technology enhancing supply chain transparency.

So, if you are ready to reinforce your operations, join us to explore ten emerging technologies that are revolutionizing the logistics industry.

Forget Spaghetti Routes, Optimize Routes for Your Entire Team with Upper

Start a 7-Day Free Trial

Table of Content

Overview of Technology in Logistics

From improving efficiency to promoting sustainability, the role of technology is crucial in driving transformation within the logistics industry. Here’s how:

Enhanced Efficiency: Technology streamlines logistics operations through automation and data analytics. Automated warehousing systems, for instance, optimize storage space and facilitate faster order fulfillment. Route optimization software utilizes real-time data to plan the most efficient routes, reducing fuel utilization and limiting delivery times.

Improved Visibility: Advanced tracking technologies like GPS and RFID tags provide real-time visibility into the location and status of shipments. This visibility helps managers anticipate delays, address issues instantly, and give precise delivery times, boosting supply chain transparency and customer satisfaction.

Driving Sustainability: Technology is essential in promoting sustainability within logistics operations. Electric vehicles (EVs) and drones provide green alternatives to diesel transport, lessening fossil fuel byproducts and pollution. AI-powered algorithms optimize routes to cut fuel usage and carbon emissions, aligning logistics with environmental goals.

Quick Adaptability: Technology empowers logistics systems to quickly adjust to changing market conditions and consumer demands. AI and machine learning algorithms analyze vast amounts of data to recognize trends and patterns, allowing logistics companies to anticipate shifts in demand and adjust inventory levels accordingly.

To sum up, technology serves more than just a tool; it’s a driving force behind the evolution of logistics, paving the way for a more efficient, resilient, and sustainable supply chain ecosystem.

Essential Tech Trends in 2025

The logistics industry is undergoing a rapid transformation. To create a flexible supply chain that drives efficiency and competitiveness, here are the essential technologies to incorporate into your strategy:

1. Robotics and automation

a. Overview of robotics and automation in logistics

Integrating robotics and automation into your logistics strategy can transform operational efficiency and productivity. Tasks such as picking, sorting, packing, and even delivery can now be automated, accelerating processes and decreasing human error.

b. Real-world applications

For example, companies like Amazon have implemented automated robotic systems in their distribution centers, significantly increasing order fulfillment rates while limiting labor costs.

c. Beyond physical tasks: Automated data analysis

Automation also extends to automated data analysis and decision-making processes. Predictive analytics algorithms can streamline inventory management, route planning, and warehouse organization, bringing about smoother operations and improved customer satisfaction.

d. Benefits of robotics and automation

By embracing robotics and automation, logistics companies can:

- Streamline processes

- Reduce expenses

- Gain a competitive advantage

2. Blockchain technology

a. What is blockchain technology in logistics?

Blockchain improves transparency, traceability, and security throughout the supply chain by creating an immutable and decentralized record of transactions.

b. Key benefits

- Real-time tracking of goods from production to delivery

- Simplified customs clearance and documentation management

- Enhanced trust and accountability among supply chain partners

c. Case study: Blockchain in action

Companies like Maersk have implemented blockchain-based platforms to digitize shipping documentation, reduce paperwork, and accelerate customs processes.

3. Artificial intelligence and machine learning

a. AI and ML in Decision-Making and Analytics

AI-powered algorithms enable logistics companies to analyze vast amounts of data, improving demand forecasting and supply chain management.

b. Applications in Route and Inventory Optimization

Route analytics and AI-driven predictive analytics optimize route planning and inventory management, enhancing resource utilization and reducing costs.

c. Customer-Centric AI Solutions

AI chatbots and virtual assistants improve customer service with real-time support and personalized recommendations, boosting satisfaction and loyalty.

d. Predictive Maintenance

AI-powered predictive maintenance systems help prevent equipment breakdowns, minimizing downtime and ensuring smoother operations.

4. Internet of Things (IoT)

a. Overview of IoT in logistics

IoT devices, such as sensors and RFID tags, provide real-time data on variables like temperature, humidity, and location, offering valuable insights into supply chain operations.

b. Applications of IoT in transportation

- Temperature monitoring for refrigerated trucks to ensure perishable goods remain within safe limits.

- Enhanced visibility of goods during transportation.

c. IoT in warehousing

IoT-enabled warehouses track product movement and storage, reducing errors and improving logistics efficiency.

d. Market growth

The global IoT in the logistics market is projected to reach over $650.5 billion by 2026, reflecting its growing importance.

5. Transportation Management Systems (TMS)

a. What is a TMS?

Transportation Management Systems (TMS) help logistics businesses manage transportation activities, including route planning, carrier selection, and shipment tracking.

b. Benefits of TMS implementation

- Optimized routes using real-time and historical data

- Reduced transportation costs and improved delivery times

c. Market outlook

Research by Allied Market Research values the TMS market at $11,367 million by 2027, with a CAGR of 9.6%.

d. Functions of a TMS

- Route planning and optimization

- Carrier management

- Shipment tracking and performance analysis

6. Data analytics and forecasting

a. Importance of data analytics

Analyzing historical and real-time data helps logistics companies gain insights into demand patterns, inventory levels, and market trends.

b. Applications in logistics

- Demand forecasting using advanced models

- Enhanced route planning and distribution processes

c. Business benefits

- Preventing stockouts and reducing excess inventory

- Improving cash flow and operational efficiency

7. Cloud logistics

a. What is cloud logistics?

Cloud-based technologies allow logistics companies to oversee and optimize supply chain activities with real-time information.

b. Applications of cloud-based solutions

- Route optimization and shipment tracking

- Performance metrics analysis to improve efficiency

c. Advantages of cloud logistics

- Scalability and adaptability to changing demands

- Enhanced transparency and collaboration across the supply chain

8. Autonomous vehicles and drones

a. Applications in last-mile delivery

Autonomous vehicles and drones reduce delivery times and costs by navigating metropolitan areas and remote locations.

b. Warehouse applications

Autonomous vehicles move goods within facilities, while drones conduct inventory checks, enhancing accuracy and efficiency.

c. Benefits of autonomous technology

- Reduced physical labor

- Improved access to remote or disaster-affected areas

9. Digital twins

a. What are digital twins?

Digital twins are virtual replicas of physical systems, enabling real-time monitoring, analysis, and optimization.

b. Applications in logistics

- Virtual replicas of warehouses and vehicles for efficiency improvements

- Predictive maintenance to prevent costly downtime

c. Business benefits

- Enhanced decision-making

- Consistent operational performance

10. Augmented Reality (AR) and Virtual Reality (VR)

a. Overview of AR and VR

AR overlays digital data on real-world environments, while VR creates fully virtual environments for training and process improvement.

b. Applications in logistics

AR for order picking, reducing errors and improving productivity

VR for training simulations in a safe, controlled setting

c. Enhanced collaboration

AR-enabled smart glasses and VR headsets allow remote experts to guide field workers, reducing travel costs and improving problem-solving.

Frequently Asked Questions

Digital logistics integrates technology into traditional logistics processes, encompassing automation to optimize operations and enhance efficiency in supply chain management. It enables streamlining inventory management, improves order accuracy, and responds to changing market demands, eventually boosting consumer loyalty and competitiveness.

When adopting new logistics technologies, companies should consider factors like scalability, compatibility with existing systems, ease of integration, potential ROI, and alignment with business goals. Additionally, assessing the technology’s reliability, support services, and regulatory compliance is significant for implementation and long-haul adequacy in streamlining warehouse operations.

While implementing digital logistics technology, companies might face challenges such as integrating new systems with existing systems, ensuring data security, and overcoming resistance to change from employees. Furthermore, ensuring compatibility with diverse supply chain partners and addressing cybersecurity concerns pose significant hurdles.

Key best practices for effectively scaling up new logistics technology include thorough planning, robust testing, employee training, seamless integration with existing systems, and agile adaptation to evolving needs. Additionally, encouraging innovation and collaboration cultivates the adoption of emerging technologies, guaranteeing sustained growth.

Technology in the logistics industry offers numerous advantages, including improved efficiency through automation, improved real-time visibility, cost savings through optimized routes, and better decision-making. Moreover, technology empowers collaboration across stakeholders, driving improvements in supply chain operations.

3D printing revolutionizes logistics and transportation by empowering on-demand manufacturing, reducing inventory storage needs, shortening lead times, and facilitating customization. Besides, 3D printing offers sustainability benefits by limiting material waste and diminishing fossil fuel byproducts associated with traditional manufacturing processes.

Future-ready Your Business with Smarter Logistics

As we have seen, logistics technologies are rapidly developing and offer great promise for improving supply chain visibility, sustainability, and cost savings in the coming years. From AI and automation to blockchain, drones, and autonomous vehicles, businesses have many options to consider. However, with all these choices, deciding the right technology to implement can appear daunting.

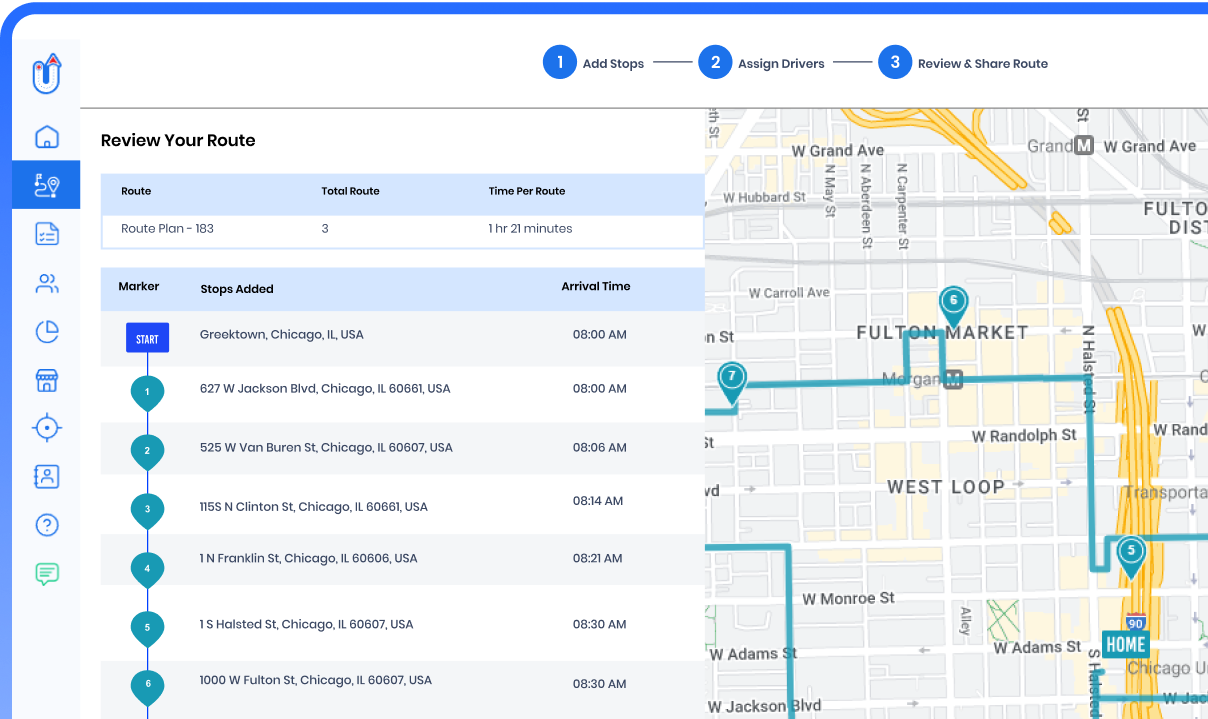

This is why innovative solutions with advanced route planning and fleet management can help optimize logistics operations. With a 7 days free trial, Upper makes it easy for logistics companies to plan and optimize routes. By thoughtfully utilizing the most effective technologies like these, businesses can guarantee they build versatile supply chains.